Mechanical maintenance and calibration of PET injection molding machine

1.Template parallelism

Template parallelism can best reflect the condition of the mold lock part, the template is not parallel will make the product unqualified and increase equipment and mold wear. The parallelism of the template can be preliminarily reflected by analyzing the movement of the tail plate and the appearance of the product when the mold is locked, but the exact situation needs to be detected by dial meter and other instruments. The adjustment of template parallelism must be carried out by professional personnel according to steps, otherwise improper adjustment will cause more damage to the machine.

2.Mold thickness adjustment

The die thickness adjustment system should be used regularly, and the die thickness should be adjusted back and forth from the thickest to the thinnest once to ensure smooth movement. For machines produced with the same die for a long time, this check must be carried out to avoid failure.

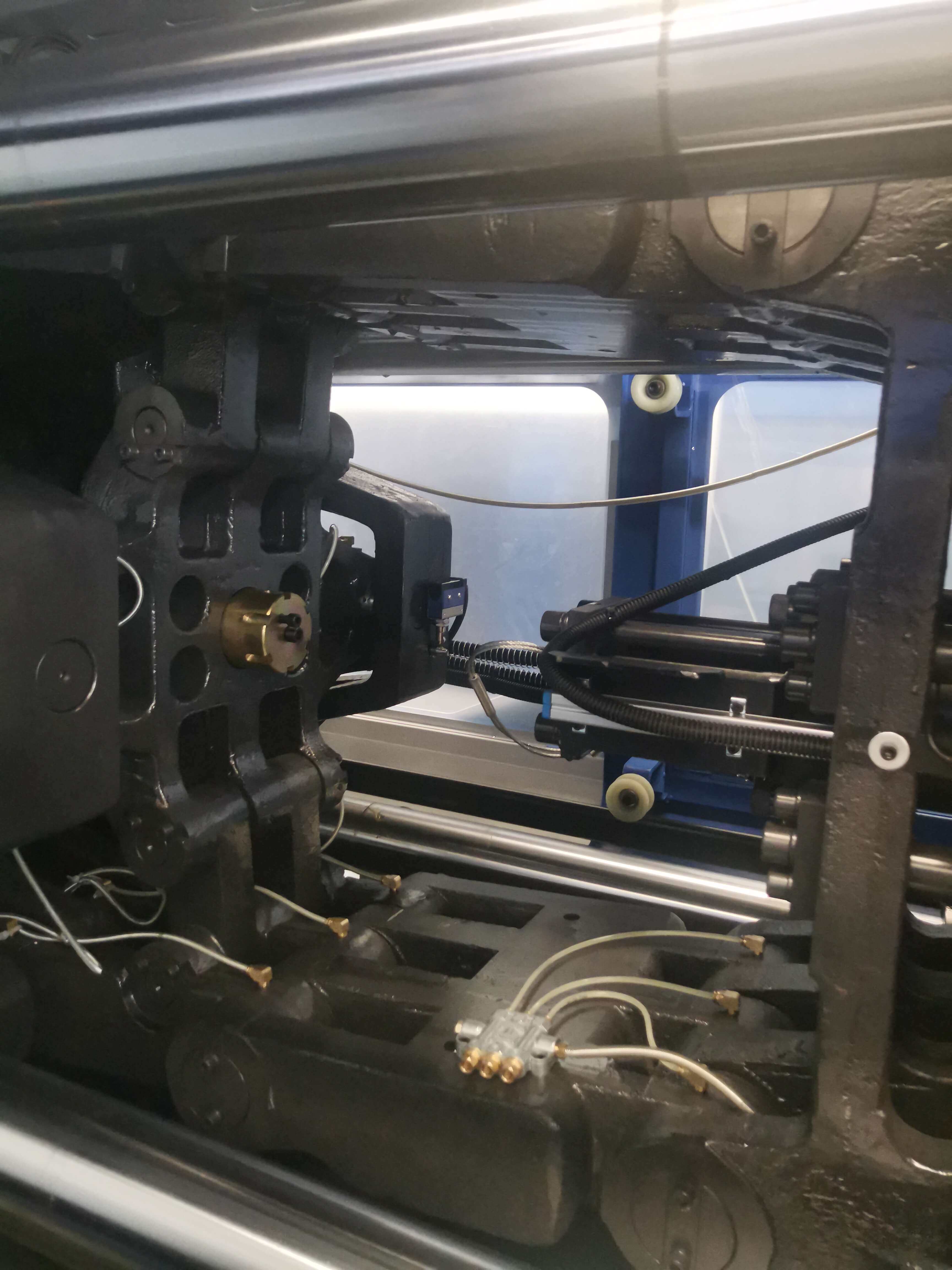

3.Central lubrication system

All mechanical parts need to be properly lubricated, central lubrication system is one of the necessary injection molding machine. The amount of oil in the central lubricating system should be checked regularly to see if it is filled up. The lubricating oil used must be clean and free of impurities to ensure that all lubricating oil locations are supplied. If oil pipe is found to be blocked or leaking, it should be replaced or repaired immediately. Most mechanical wear occurs due to lack of lubrication, so adequate attention should be paid to lubrication.

4.Keep everything smooth

Motion vibration or not smooth may be due to improper speed adjustment, speed change and time uncoordinated or mechanical, oil pressure regulation caused. This kind of vibration will accelerate the wear of the mechanical parts and loosen the fastening screws. Therefore, vibration should be reduced and avoided.

5.Bearing inspection

Bearing at work when there are abnormal sound, or temperature rise, or difficult rotation means that the bearing has been worn, should be checked or replaced in time, and re-injection of grease. Such as: storage motor drive system.

6.Injection system

The injection screw, check ring and barrel constitute the heart part of the injection molding machine, which determines the quality and efficiency of processing. They must be kept in good working condition. First of all, necessary measures should be taken to prevent non-plastic debris from mixing into the plastic material flow. Furthermore, attention should be paid to checking the correct clearance between the screw and the barrel, and the check ring and the barrel. The normal clearance should be able to seal the plastic backflow and produce the shear action required for plasticizing. Or product forming unstable should check the screw, check ring and barrel wear.